-

Stainless Steel Seamless Pipe

-

Stainless Steel Welded Pipe

-

Stainless Steel Pipe Fittings

-

Stainless Steel Sanitary Pipe

-

Duplex Stainless Steel Pipe

-

Bright Annealed Tube

-

Stainless Steel Heat Exchanger Tube

-

Stainless Steel Round Rod

-

Stainless Steel Flange

-

Stainless Steel Valve

-

Nickel Alloy Pipes

-

Screwed Pipe Fittings

-

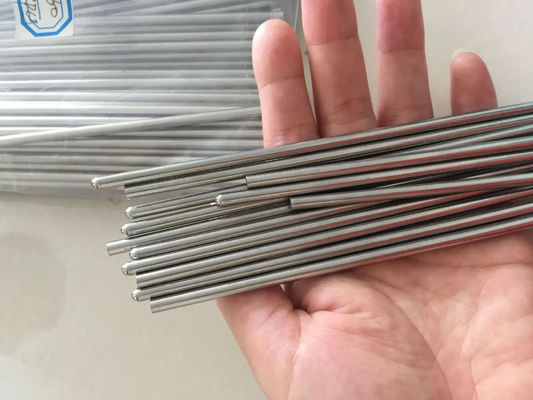

Stainless Steel Capillary Tube

-

Sam"Wenzhou Shangle Steel's products are truly game-changers. Their stainless steel pipes have not only streamlined our operations but also boosted overall efficiency. High quality, reliable, and durable, they are a valuable addition to our projects!"

Sam"Wenzhou Shangle Steel's products are truly game-changers. Their stainless steel pipes have not only streamlined our operations but also boosted overall efficiency. High quality, reliable, and durable, they are a valuable addition to our projects!" -

Peter"Choosing Wenzhou Shangle Steel is one of the best decisions we've made. Their commitment to quality and customer service is unparalleled. The stainless steel pipes we procured became integral to our manufacturing process and significantly improved our productivity!"

Peter"Choosing Wenzhou Shangle Steel is one of the best decisions we've made. Their commitment to quality and customer service is unparalleled. The stainless steel pipes we procured became integral to our manufacturing process and significantly improved our productivity!"

ASTM A269 TP304 SS316L STAINLESS STEEL CAPILLARY TUBE BRIGHT ANNEALED

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | 304 ,304L 310 321 316 316L | Standard | AISI, ASTM, DIN, EN, GB |

|---|---|---|---|

| Shape | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80 | Technique | Cold Draw |

| Application | Oil, Petroleum/Power | Package | Woven Packing |

| Highlight | SS316L STAINLESS STEEL CAPILLARY TUBE,petroleum STAINLESS STEEL CAPILLARY TUBE,BRIGHT ANNEALED STAINLESS STEEL CAPILLARY TUBE |

||

ASTM A269 TP304 SS316L STAINLESS STEEL CAPILLARY TUBE BRIGHT ANNEALED

SS Capillary Tube Seamless is designed to change the high pressure liquid refrigerant into a low pressure spray of refrigerant. Its pressure drop amount is dependent on the length and inside diameter of the tube. 316 SS Capillary Tubing is the standard molybdenum bearing grade tube. It provides better corrosion resistant properties than 304 SS Capillary Tubing, especially higher resistance to pitting and crevice corrosion in chloride environments. 316 Stainless Steel Capillary Tubing For Hplc are components in both liquid and gas chromatography columns which are used for preparative and analytical processes across the fields of analytical and biochemistry.

During manufacture the control process of these tubes is critical in order to meet the highest specifications demanded in this area. SS Evaporator Coil Capillary Tube is durable and corrosion resistant, which makes it a wise choice for corrosive surroundings. It also has high tensile strength. It reduces the possibility of leaks in evaporator coils because it is corrosion resistant. Since salt is corrosive, buildings located near the salty locations will benefit from stainless steel evaporator coil capillary tubes. Many industries such as oil & gas, chemical, food & beverage and pharmaceutical will also benefit from it.

Medical Tubes

- Tubes for a wide range of medical applications.

- Yuhong's program of medical tubes covers stainless steel tubing for cardiovascular and diagnostic applications, dental and surgical instruments as well as medical tubes for reconstruction, trauma and spinal use. Our in-house production of medical tubes allows for tailor-made sizes in small batches.

- Medical tube materials (other grades can be offered on request)

Tolerance of SS Capillary Tubes

| SIZE OD | NOMINAL WALL THICKNESS | OUTSIDE DIAMETER TOLERANCE | LENGTH TOLERANCE | WALL THICKNESS TOLERANCE | ||||

| (in) | (mm) | (in) | (mm) | (in) | (mm) | (in) | (mm) | (%) |

| ½ | 12.7 | 0.065 | 1.65 | +/-0.005 | +/-0.13 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| ¾ | 19.1 | 0.065 | 1.65 | +/-0.005 | +/-0.13 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 1 | 25.4 | 0.065 | 1.65 | +/-0.005 | +/-0.13 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 1½ | 38.1 | 0.065 | 1.65 | +/-0.008 | +/-0.20 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 2 | 50.8 | 0.065 | 1.65 | +/-0.008 | +/-0.20 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 2½ | 63.5 | 0.065 | 1.65 | +/-0.010 | +/-0.25 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 3 | 76.2 | 0.065 | 1.65 | +/-0.010 | +/-0.25 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 4 | 101.6 | 0.083 | 2.11 | +/-0.015 | +/-0.38 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 6 | 152.4 | 0.109 | 2.77 | +/-0.030 | +/-0.76 | +1, -0 | +25.4, -0 | +/-10.0% |

Chemical Composition of SS316

| Stainless Steel Capillary Tube Grades | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16-18 | 11-14 | 2-3 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16-18 | 10-14 | 2-3 |

SS capillary tube Mechanical Characteristics

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

Equivalent Grades Of SS316 Capillary Tubing

| GRADE | UNS NO | DIN/WERKSTOFF |

| Stainless Steel Capillary Tube 316 | S31600 | 1.4436 |

| Stainless Steel Capillary Tube 316L | S31603 | 1.4404 |

Application:

- Petrochemical industry: stainless steel capillary tubes can be used for transportation equipment in petroleum refining, chemical industry and other processes. They can resist corrosion, wear, temperature, cold and durability, and can greatly improve work efficiency.

- Water treatment: stainless steel capillary tubes can be used for drinking water treatment and other water treatment processes. They have the function of preventing the growth of bacteria and can improve the quality of water quality.

- Automobile industry: stainless steel capillary tubes can be used in the refrigeration system, fuel system, and diesel system of automobile engines, and can resist the application of various high temperature, low temperature, and low temperature freezing environments, making the service life of automobiles longer.

- Air conditioning refrigeration: stainless steel capillary tubes can be used in air conditioning systems, which can make the air conditioning more power-saving, strong corrosion resistance, and can work normally for a long time.

- Electric power: stainless steel capillary tubes can be used in electric power industry, such as hydropower stations, thermal power stations, etc., which can resist high temperature, low temperature and humid environment and improve work efficiency.