-

Stainless Steel Seamless Pipe

-

Stainless Steel Welded Pipe

-

Stainless Steel Pipe Fittings

-

Stainless Steel Sanitary Pipe

-

Duplex Stainless Steel Pipe

-

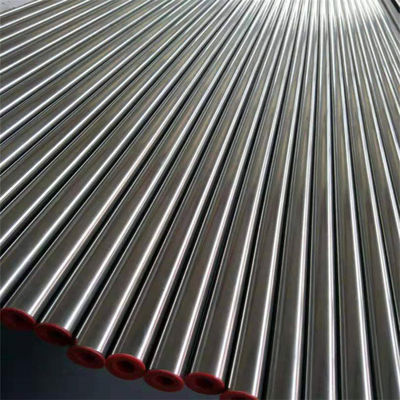

Bright Annealed Tube

-

Stainless Steel Heat Exchanger Tube

-

Stainless Steel Round Rod

-

Stainless Steel Flange

-

Stainless Steel Valve

-

Nickel Alloy Pipes

-

Screwed Pipe Fittings

-

Stainless Steel Capillary Tube

-

Sam"Wenzhou Shangle Steel's products are truly game-changers. Their stainless steel pipes have not only streamlined our operations but also boosted overall efficiency. High quality, reliable, and durable, they are a valuable addition to our projects!"

Sam"Wenzhou Shangle Steel's products are truly game-changers. Their stainless steel pipes have not only streamlined our operations but also boosted overall efficiency. High quality, reliable, and durable, they are a valuable addition to our projects!" -

Peter"Choosing Wenzhou Shangle Steel is one of the best decisions we've made. Their commitment to quality and customer service is unparalleled. The stainless steel pipes we procured became integral to our manufacturing process and significantly improved our productivity!"

Peter"Choosing Wenzhou Shangle Steel is one of the best decisions we've made. Their commitment to quality and customer service is unparalleled. The stainless steel pipes we procured became integral to our manufacturing process and significantly improved our productivity!"

Heat Exchanger Tube ASME SA213 TP304 Stainless Steel Seamless Bright Annealed Tube

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | 304 ,304L 310 321 316 316L | Standard | AISI, ASTM, DIN, EN, GB |

|---|---|---|---|

| Shape | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80 | Technique | Cold Draw |

| Application | Oil, Petroleum/Power | Package | Woven Packing |

| Highlight | Heat Exchanger Tube Stainless Steel,ASME SA213 TP304 Stainless Steel Tube,TP304 Seamless Bright Annealed Tube |

||

Heat Exchanger Tube ASME SA213 TP304 Stainless Steel Seamless Bright Annealed Tube

ASTM A213 TP304 Stainless Steel Seamless Bright Annealed Tube has the addition of nickel, nitrogen, manganese, which makes the steel have good weldability and formability. The corrosion resistance ability can be improved by augmenting the process. TP304 can be hardened by cold working process, retaining the strength and ductility. Our YUHONG GROUP is professional in manufacturing stainless steel seamless bright annealed tubes with high quality.

Specifications:

| Specification | ASTM A213 / ASME SA213 TP304 |

| Shapes | Round |

| Thickness Range | SCH 10 - SCH XXS |

| Surface Finish | Bright Annealed |

| Manufacturing Type | Seamless / Welded / ERW |

| Standard | GB, JIS, DIN, ASTM, AISI, EN, SUS |

| Technique | Cold rolled, Extrusion, Cold drawn, Hot rolled Tube |

| Delivery Condition | Polished, Annealed and Pickled (AP), MF, Cold Drawn, Bright Annealed (BA) |

| Ends | Plain End, Treaded, Beveled End |

Equivalent Grades:

| Grade | UNS No | Old British | Euronorm | SS | JIS | ||

| BS | En | No | Name | ||||

| SS 304 | S30400 | 304S31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304 |

Outside Diameter & Wall Thickness Permissible Variations:

| OD,mm | W.T,mm | |

| ≤25.4 | ±0.10 | +20%, 0%, OD>50,W T>5.6 AVG Wall +/-10% |

| 25.4~38.1 | ±0.15 | |

| 38.1~50.8 | ±0.2 | |

| 50.8~63.5 | ±0.25 | |

| 63.5~76.2 | ±0.3 | |

| 76.2~101.6 | ±0.38 | |

Chemical Compositions:

| C | 0.08 max |

| Mn | 2 max |

| Si | 0.75 max |

| P | 0.045 max |

| S | 0.03 max |

| Cr | 18 – 20 |

| Ni | 8 – 11 |

Mechanical Properties:

| Tensile Stress (MPa) | Yield Stress 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Limit | |

| Rockwell B (HR B) | Brinell (HB) | |||

| 515 min | 205 min | 40 min | 92 max | 201 max |

Applications:

Water Supply Systems

Paper & Pulp Industry

Power Plant

Fabrication Industry

Chemical Industry

Structural Tube

Oil and Gas Tubeline

Nuclear Industry

Petro-Chemical industry

Food and Beverages

Shell and Tube Heat Exchangers

![]()